Product Overview

30 Durometer FDA Grade Solid Silicone — Technical Overview & FAQs

Product Overview

30 Durometer FDA Grade Solid Silicone Rubber is an extra-soft, highly flexible, platinum-cured silicone elastomer formulated to meet FDA 21 CFR 177.2600 requirements for food contact, beverage applications, medical equipment, and hygienic sealing environments.

At 30 Shore A, this material offers exceptional softness and compressibility, making it ideal for low-pressure sealing, sanitary gaskets, peristaltic pump components, and delicate enclosure seals where a gentle sealing response is required.

This FDA-compliant silicone delivers excellent stability across extreme temperatures, combined with outstanding resistance to UV, ozone, steam, and cleaning chemicals commonly used in sanitary environments.

Applications

Food and beverage processing equipment

Seals and gaskets for sanitary systems

Pharmaceutical and laboratory equipment

Low-compression food-safe enclosure seals

Medical device components (non-implant)

Peristaltic pump tubing interfaces (depending on durometer design)

Die-cut FDA-compliant silicone gaskets and pads

Key Properties

Material Type: FDA Grade Solid Silicone Rubber

Durometer: 30 Shore A (extra-soft, high flexibility)

FDA Compliance: FDA 21 CFR 177.2600

Tensile Strength: Moderate, suitable for soft sanitary sealing

Elongation: High, excellent elasticity and recovery

Compression Set: Low — maintains sanitary sealing integrity

Temperature Range: –80 °F to +450 °F (–62 °C to +232 °C)

Environmental Resistance: UV, ozone, steam, and weather-resistant

Chemical Resistance: Resistant to cleaning agents, sanitizers, water, and mild chemicals

Color Options: Typically natural/translucent or white (FDA grade)

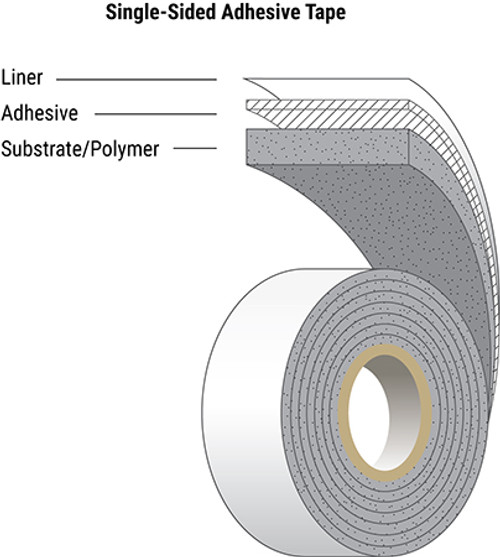

Available Formats: Sheets, rolls, strips, die-cut gaskets, extruded profiles, PSA-backed

Compliance: FDA 21 CFR 177.2600 | RoHS | REACH

FAQs

What is 30 Durometer FDA Grade Silicone used for?

It is used for food-safe and sanitary sealing applications, including food processing equipment, beverage systems, medical equipment housings, lab devices, and low-compression hygienic gaskets.

Is 30 durometer silicone safe for food contact?

Yes — it meets FDA 21 CFR 177.2600, making it suitable for applications where incidental food contact occurs.

Why choose a 30A softness level?

30A silicone is extremely soft and flexible, making it ideal for:

Low-fastener-load sealing

Delicate enclosures

Soft sanitary gasketing

Components requiring high elasticity

Does FDA silicone withstand high temperatures and steam?

Yes — it performs reliably from –80 °F to +450 °F and offers excellent resistance to steam, hot water, and cleaning chemicals used in sanitary environments.

Can FDA silicone be supplied as custom-cut gaskets or adhesive-backed?

Absolutely — H-O Products offers die-cut FDA silicone gaskets, PSA-backed parts, strips, sheets, and precision-fabricated sanitary components.

Contact H-O Products to request 30 Durometer FDA Grade Solid Silicone samples, compliance documentation, or custom sanitary gasket solutions - contact us.