Product Overview

60 Durometer FDA Grade Solid Silicone — Technical Overview & FAQs

Product Overview

60 Durometer FDA Grade Solid Silicone Rubber is a firm, platinum-cured silicone elastomer engineered for food-contact safety, industrial durability, and high mechanical stability.

Fully compliant with FDA 21 CFR 177.2600, this material is odorless, tasteless, non-toxic, and ideal for medium-to-high compression sanitary sealing where enhanced structural strength is required.

With a firmness of 60 Shore A, this grade offers excellent resistance to deformation under load, improved sealing pressure, and superior durability for food processing, pharmaceutical equipment, sanitary enclosures, and high-temperature manufacturing environments.

Applications

Medium-to-high compression sanitary gaskets

High-temperature food equipment seals

Beverage and dispensing system components

Pharmaceutical manufacturing and cleanroom systems

Medical and laboratory device housings (non-implant)

FDA-compliant die-cut gaskets, strips, pads, and extruded profiles

Key Properties

Material Type: FDA Grade Solid Silicone

Durometer: 60 Shore A (firm sanitary silicone rubber)

FDA Compliance: Meets FDA 21 CFR 177.2600

Mechanical Strength: Higher tensile strength vs. softer FDA grades

Compression Set: Very low — maintains high-pressure sealing performance

Elongation: Moderate flexibility with firm mechanical stability

Temperature Range: –80 °F to +450 °F (–62 °C to +232 °C)

Environmental Resistance: UV, ozone, moisture, and steam resistant

Chemical Resistance: Excellent resistance to sanitizers, detergents, and CIP washdowns

Color Options: Translucent, white, red iron oxide, or cstom FDA-compliant colors

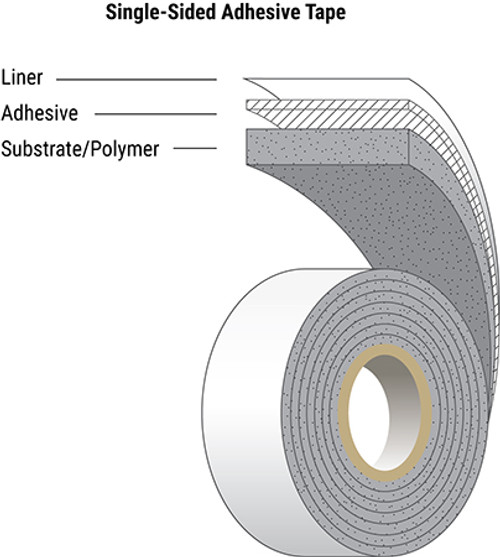

Formats Available: Sheets, rolls, strips, extrusion profiles, die-cut gaskets, PSA-backed parts

Compliance: FDA 21 CFR 177.2600 | RoHS | REACH

FAQs

What is 60 Durometer FDA Grade Silicone used for?

It is used for durable sanitary gaskets, food equipment seals, pharmaceutical devices, and high-pressure FDA-compliant sealing applications requiring firm, long-lasting performance.

Is 60 durometer silicone safe for food-contact applications?

Yes — it is fully compliant with FDA 21 CFR 177.2600 and safe for incidental food contact in processing, dispensing, and sanitary manufacturing environments.

What makes 60A FDA silicone different from softer grades?

60A silicone is significantly firmer, providing:

Higher sealing pressure

Improved structural support

Greater resistance to compression and deformation

Longer service life in industrial environments

Does 60 durometer silicone withstand high temperatures and sanitation cycles?

Yes — it remains stable from –80 °F to +450 °F, resisting:

Steam

Hot water

Cleaning and CIP chemicals

Repeated sanitation cycles without degradation

Can FDA silicone be die-cut or supplied with adhesive backing?

Absolutely — H-O Products manufactures die-cut sanitary gaskets, PSA-backed components, strips, sheets, and custom OEM sanitary parts.

Contact H-O Products today for 60 Durometer FDA Grade Solid Silicone samples, custom sanitary gasket fabrication, or FDA compliance documentation - contact us.