Product Overview

70 Durometer FDA Grade Solid Silicone — Technical Overview & FAQs

Product Overview

70 Durometer FDA Grade Solid Silicone Rubber is a firm, high-strength, platinum-cured silicone elastomer designed for applications requiring food-contact safety, high mechanical durability, and strong sealing pressure.

Fully compliant with FDA 21 CFR 177.2600, this material is odorless, tasteless, chemically inert, and suitable for food, beverage, pharmaceutical, and sanitary environments where firm gasket materials are essential.

At 70 Shore A, this grade provides excellent dimensional stability, high tensile strength, and low compression under load, making it ideal for high-pressure sealing, equipment housings, food machinery components, and industrial sanitary systems operating in demanding thermal or chemical environments.

Applications

High-pressure sanitary gaskets

Food-processing and beverage equipment seals

Pharmaceutical and bioprocessing systems

Industrial and sanitary enclosures requiring firm sealing

Oven, heater, and high-temperature food-grade components

FDA-compliant die-cut gaskets, strips, extruded profiles, and custom OEM parts

Key Properties

Material Type: FDA Grade Solid Silicone Rubber

Durometer: 70 Shore A (firmest standard FDA grade)

FDA Compliance: Meets FDA 21 CFR 177.2600

Mechanical Strength: High tensile and tear resistance

Compression Performance: Very low deflection under load (strong sealing pressure)

Elongation: Moderate — provides structural stability and reliable sealing

Temperature Range: –80 °F to +450 °F (–62 °C to +232 °C)

Environmental Resistance: Excellent UV, ozone, moisture, and steam resistance

Chemical Resistance: Withstands sanitizers, cleaning agents, and CIP washdowns

Color Options: White, translucent, red iron oxide, or custom sanitary colors

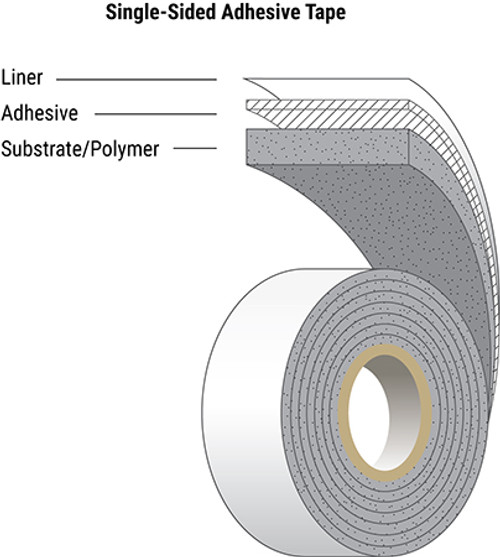

Available Formats: Sheets, rolls, strips, PSA-backed formats, die-cut gaskets, extrusions

Compliance: FDA 21 CFR 177.2600 | RoHS | REACH

FAQs

What is 70 Durometer FDA Grade Silicone used for?

It is used for high-pressure sanitary gaskets, food-processing equipment, pharmaceutical manufacturing systems, and industrial sanitary sealing where firm silicone rubber is required.

Is 70 durometer silicone safe for food-contact applications?

Yes. This material is fully compliant with FDA 21 CFR 177.2600, making it suitable for incidental food-contact sealing in food, beverage, and hygienic processing equipment.

How firm is 70 durometer silicone compared to softer FDA grades?

70A silicone is the firmest standard FDA silicone, offering:

Maximum structural rigidity

Minimal compression under load

Excellent long-term sealing pressure

Superior resistance to deformation

Can this material withstand high temperatures and sanitation cycles?

Yes — it performs reliably from –80 °F to +450 °F, and provides outstanding resistance to:

Steam

CIP cleaning chemicals

Sanitizing agents

Hot water washdowns

Can 70A FDA silicone be die-cut or fabricated into custom parts?

Absolutely — H-O Products supplies die-cut gaskets, strips, extruded profiles, PSA-backed components, and custom OEM sanitary parts made from this material.

Contact H-O Products to request 70 Durometer FDA Grade Solid Silicone samples, custom gasket fabrication, or FDA compliance documentation - contact us.