Product Overview

70 Durometer Industrial Grade Solid Neoprene — Technical Overview & FAQs

Product Overview

The 70 durometer industrial-grade solid neoprene (polychloroprene, CR) sheet is a firm, durable elastomer developed for high-load sealing, vibration isolation, and gasketing applications.

With a Shore A hardness of 70, this material delivers excellent mechanical strength, compression-set resistance, and environmental stability in tough industrial conditions.

It performs reliably in both indoor and outdoor environments where moderate oil, ozone, and weather exposure occur — ideal for flanged seals, mounting pads, and heavy-duty equipment gaskets.

Applications

High-load gaskets and seals for machinery and enclosures

Industrial vibration and shock isolation pads

Mounting blocks, spacers, and protective bumpers

Weather-resistant mechanical pads and door seals

Adhesive-backed components for vibration and sealing control

Key Properties

Hardness: Shore A 70 ± 5 (ASTM D2240)

Tensile Strength: ≈ 1000 psi (ASTM D412)

Elongation at Break: ≥ 200 % (ASTM D412)

Compression Set (22 h @ 158 °F): ≤ 25 %

Temperature Range: –20 °F to +220 °F (–29 °C to 104 °C)

Specific Gravity: ≈ 1.38 g/cc

Polymer Type: Polychloroprene (CR)Color / Finish: Black – Smooth, powder-free sheet

Environmental Resistance: Excellent ozone & weather resistance; moderate oil resistance

Compliance: RoHS and REACH compliant

FAQs

What is 70 durometer industrial grade solid neoprene used for?

This firm neoprene rubber is used for heavy-duty gaskets, vibration pads, spacers, and seals in equipment and structures requiring strength and environmental durability.

How firm is 70 durometer neoprene compared to other grades?

70 Shore A is the firmest standard grade in the industrial neoprene range — it provides superior load-bearing capacity and compression resistance versus softer 50 or 60 durometer materials.

What temperature range can it handle?

This material operates reliably from –20 °F to +220 °F (–29 °C to 104 °C), maintaining sealing performance and mechanical strength under thermal cycling.

Is this neoprene suitable for outdoor or chemical exposure?

Yes — it exhibits excellent resistance to ozone, sunlight, and weathering, and moderate resistance to petroleum oils and lubricants, making it ideal for industrial and outdoor use.

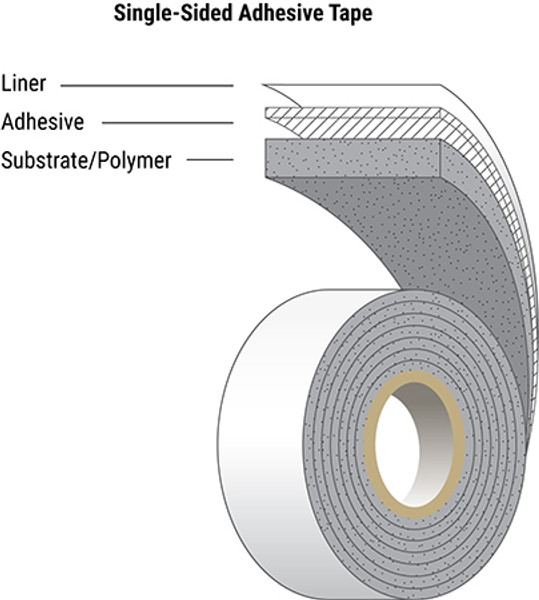

Can this material be custom fabricated or adhesive-backed?

Yes — it can be supplied as sheets, rolls, or die-cut gaskets, with optional acrylic or rubber PSA backing for easy peel-and-stick installation.

Request H-O Products 70 Durometer Industrial Grade Solid Neoprene samples, technical data, or custom die-cut fabrication for your next industrial sealing or vibration-control application - contact us.