Product Overview

90 Durometer Commercial Grade Solid Silicone — Technical Overview & FAQs

Product Overview

90 Durometer Commercial Grade Solid Silicone Rubber is an extremely firm, high-strength silicone elastomer engineered for applications requiring maximum rigidity, minimal deflection, and exceptional mechanical stability.

At 90 Shore A, this is one of the firmest silicone rubber grades available, offering near-plastic rigidity while maintaining silicone’s hallmark benefits—broad temperature resistance, chemical stability, UV/ozone durability, and long-term resilience.

This ultra-firm silicone is ideal for high-load compression seals, structural interface components, vibration isolation pads, mechanical supports, and industrial or aerospace assemblies requiring very low compression and high mechanical strength.

Applications

Ultra-firm, high-pressure industrial gaskets

Load-bearing silicone components

Structural interface pads and mechanical supports

High-stress transportation and aerospace sealing

Equipment mounting and anti-vibration isolators

Electrical enclosure and equipment housing barriers

Heavy-duty die-cut and machined silicone parts

Key Properties

Durometer: 90 Shore A (ultra-firm silicone grade)

Mechanical Strength: Very high tensile and tear resistance

Compression Resistance: Maximum load support with minimal deflection

Elongation: Lower than softer grades but maintains controlled flexibility

Temperature Range: –80 °F to +450 °F (–62 °C to +232 °C)

Environmental Resistance: Excellent resistance to UV, ozone, humidity, and outdoor exposure

Chemical Resistance: Good resistance to oils, solvents, and oxidation

Electrical: Reliable dielectric insulation properties

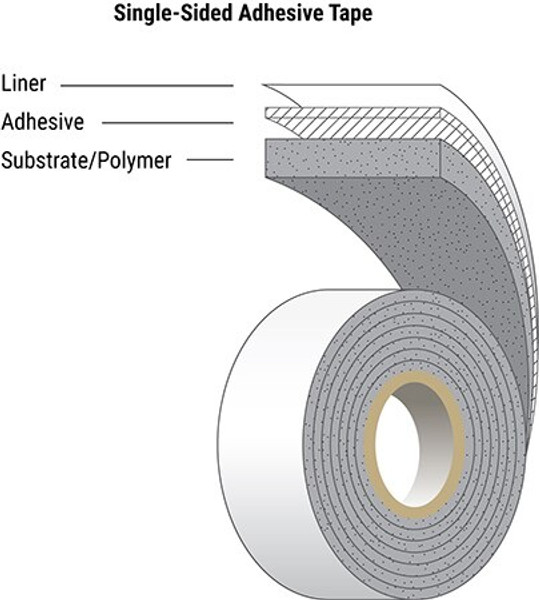

Formats Available: Sheets, rolls, strips, extrusions, die-cut parts, PSA-backed

Compliance: RoHS | REACH

FAQs

What is 90 Durometer Solid Silicone used for?

It is used for high-pressure sealing, load-bearing components, rigid gasket interfaces, and mechanically demanding industrial applications where maximum firmness is required.

How firm is 90 durometer silicone?

90A silicone is extremely firm, providing:

Minimal compression under high loads

Near-plastic rigidity

Maximum dimensional stability

Superior mechanical durability

It is the firmest commonly used commercial silicone grade.

Is 90 durometer silicone suitable for outdoor use?

Yes. Silicone provides exceptional UV, ozone, and weather resistance, ensuring reliability in harsh and long-term outdoor environments.

Can 90 durometer silicone withstand high temperatures?

Absolutely. It performs reliably from –80 °F to +450 °F, making it suitable for high-heat industrial, automotive, aerospace, and electrical applications.

Can this material be die-cut, machined, or PSA-backed?

Yes — H-O Products manufactures die-cut gaskets, machined silicone parts, PSA-backed seals, strips, and custom-engineered ultra-firm silicone components for OEM use.

Contact H-O Products for 90 Durometer Commercial Grade Solid Silicone samples, application engineering support, or custom-fabricated sealing solutions - contact us.