Product Overview

AFTC AM1011HC General Purpose Tape — Technical Overview & FAQs

What is AFTC AM1011HC General Purpose Tape?

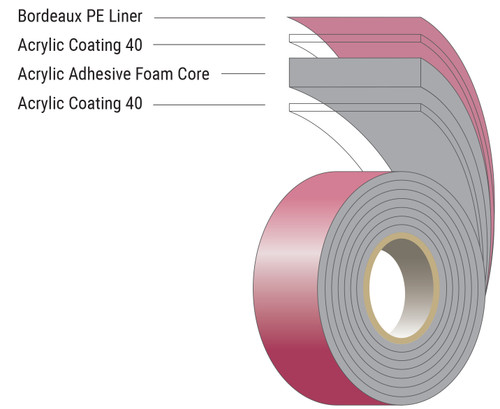

AFTC AM1011HC is a high-strength, general-purpose acrylic foam bonding tape engineered for permanent attachment to metals, high-surface-energy plastics, composites, and coated materials. Featuring a durable acrylic foam core and a high-performance pressure-sensitive adhesive, AM1011HC provides excellent shear, peel, and environmental resistance for a broad range of industrial bonding applications.

Designed as a versatile alternative to traditional mechanical fasteners, AM1011HC offers clean, uniform bonding that enhances product durability and visual quality.

Where is AFTC AM1011HC typically used?

• Metal-to-metal and metal-to-plastic bonding

• General industrial assembly

• Appliance components, panels, and trim

• Automotive interior and exterior attachment

• Signage, displays, and nameplates

• Applications requiring a strong, permanent, general-purpose adhesive tape

What makes AFTC AM1011HC different from other acrylic foam tapes?

• High-strength general-purpose formulation suitable for a wide range of substrates

• Excellent peel adhesion and long-term shear performance

• Strong bonding to metals, HSE plastics, composites, and coatings

• Durable acrylic foam core absorbs vibration and stress

• Resistant to moisture, chemicals, UV exposure, and temperature cycling

• Cleaner, faster installation compared to rivets, screws, or liquid adhesives

• Available in multiple widths, thicknesses, and converter-ready formats

Is AFTC AM1011HC weather- and UV-resistant?

Yes. AM1011HC is engineered for outdoor durability, offering long-term resistance to:

• UV light

• temperature extremes

• moisture and humidity

• chemical exposure

• vibration and mechanical stress

It maintains adhesive strength and structural integrity even in demanding environments.

Is AFTC AM1011HC safe for automotive, appliance, or industrial assembly?

Yes. AM1011HC is widely used in:

• automotive trim, panel, and bracket attachment

• consumer and commercial appliances

• industrial equipment and enclosures

• architectural and manufacturing applications

It is non-corrosive, dimensionally stable, and designed for long-term performance.

Key Mechanical & Adhesive Properties

Typical performance characteristics of AFTC AM1011HC General Purpose Acrylic Foam Tape include:

Tape Type: General-purpose high-strength acrylic foam tape

Foam Structure: Conformable acrylic foam for durable bonding

Standard Thickness: Approx. 1.1 mm (may vary by region)

Peel Adhesion: High—designed for strong metal and HSE plastic bonding

Static Shear Strength: Excellent long-term load-bearing capacity

Tensile Strength: Strong acrylic foam core supports structural bonding loads

Temperature Resistance: Typically –40 °F to +300 °F (–40 °C to +150 °C)

UV & Weather Resistance: Excellent for indoor or outdoor exposure

Environmental Performance: Resistant to chemicals, moisture, vibration, and temperature cycling

How does it perform in outdoor and industrial environments?

AFTC AM1011HC is designed for extreme environmental reliability, offering:

• stable adhesion under temperature swings

• long-lasting UV resistance

• strong moisture and chemical resistance

• vibration and stress absorption through the acrylic foam core

Its reliable performance makes it suitable for both indoor and outdoor applications across multiple industries.

Can AFTC AM1011HC be die-cut or converted?

Yes. AM1011HC is fully converter-friendly and can be supplied as:

• precision die-cut parts

• kiss-cut pads

• custom slit rolls

• laminated constructions

• pre-tabbed adhesive components for OEM assembly

Converters can create complex geometries for high-volume manufacturing lines.

What formats are available?

• Standard rolls (various widths)

• Custom slit rolls

• Die-cut components

• OEM-ready bonding pads and assemblies

Ready to evaluate AFTC AM1011HC for your bonding application?

Contact our team to request samples, discuss performance requirements, or receive a custom quote for AFTC AM1011HC General Purpose Tape.

Need help selecting the right tape? Our application specialists can help you choose the ideal thickness, adhesion level, and converting options for your project - contact us.