Product Overview

AFTC 5313 Direct Foam Tape — Technical Overview & FAQs

Product Overview

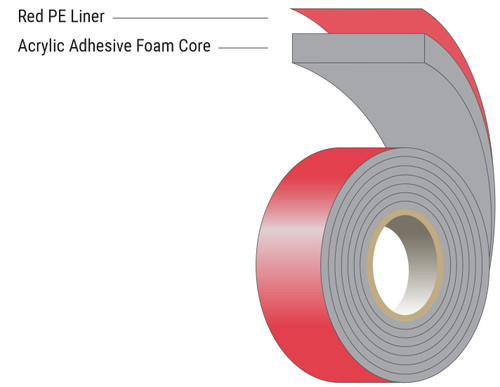

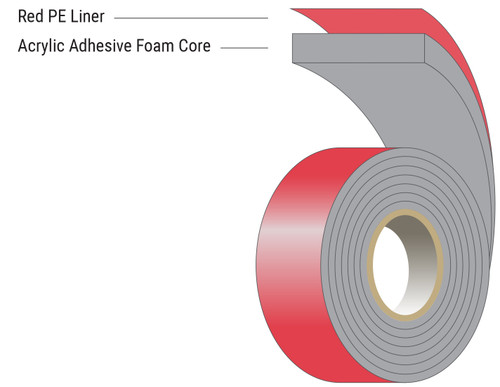

AFTC 5313 Direct Foam Tape is a premium acrylic direct-foam bonding tape engineered for plastic-to-plastic, plastic-to-metal, and composite bonding.

Unlike traditional acrylic foam tapes, AFTC 5313 uses a direct-foamed acrylic core, meaning the foam and adhesive chemistry are fully integrated — improving cohesive strength, durability, compressibility, and surface wet-out.

AFTC 5313 is formulated with a high-tack, plastic-optimized acrylic adhesive, delivering exceptional adhesion to low-, medium-, and high-surface-energy plastics including ABS, PVC, acrylic, polycarbonate, and painted or coated polymer surfaces.

This tape offers outstanding conformability and is ideal for textured, uneven, or contoured plastic surfaces, making it a preferred solution in automotive interiors, consumer electronics, appliances, HVAC components, signage, and general OEM assembly.

Applications

Plastic-to-plastic bonding in electronics, appliances, and consumer goods

Automotive trim, instrument panel bonding, and decorative plastic components

HVAC and appliance plastic mounting

POP displays, signage, and acrylic sheet bonding

Composite-to-plastic structural bonding

OEM production lines requiring high-performance acrylic foam technology

Key Properties

Material Type: Direct-foamed acrylic adhesive tape

Adhesive System: High-tack acrylic adhesive optimized for plastics

Core Structure: Integrated direct-foam acrylic core for enhanced strength

Adhesion Strength: Excellent adhesion to ABS, acrylic, PVC, PC, and painted plastics

Peel Strength: High peel resistance for permanent bonding

Shear Performance: Strong cohesive strength for structural assemblies

Conformability: Superior ability to bond to textured, uneven, or contoured surfaces

Durability: UV-, moisture-, and chemical-resistant for long-term use

Thermal Stability: Maintains bond integrity through heat and cold cycling

Convertibility: Ideal for precision die-cutting in OEM adhesive components

FAQs

What is AFTC 5313 Direct Foam Tape used for?

AFTC 5313 is used for high-strength bonding of plastics, metals, and composites in automotive interiors, electronics housings, appliances, POP displays, signage, and OEM plastic assemblies.

What makes AFTC 5313 different from standard acrylic foam tapes?

AFTC 5313 uses a direct-foam acrylic core, which provides:

Higher cohesive strength

Better stress distribution

Improved wet-out on plastics

Enhanced bonding to textured or uneven surfaces

Superior vibration and impact absorption

Which plastics does AFTC 5313 bond best?

AFTC 5313 bonds exceptionally well to:

ABS

Acrylic (PMMA)

Polycarbonate (PC)

PVC

Painted plastics

Coated polymer surfaces

Composite substrates

Is AFTC 5313 suitable for outdoor environments?

Yes. AFTC 5313 offers long-term durability under UV exposure, moisture, solvents, and temperature cycling, making it suitable for both indoor and outdoor applications.

Can AFTC 5313 be die-cut into custom parts?

Absolutely. H-O Products produces precision die-cut AFTC 5313 components for OEM assembly lines and automated production.

Contact H-O Products today to order AFTC 5313 Direct Foam Tape in rolls, logs, or custom die-cut components — or request engineering support to optimize your plastic bonding application - contact us.