Product Overview

AFTC 5330 Direct Foam Tape — Technical Overview & FAQs

Product Overview

AFTC 5330 Direct Foam Tape is a high-strength, direct-foamed acrylic bonding tape engineered for plastic-to-plastic, plastic-to-metal, and composite assemblies.

Made using true direct-foam acrylic technology—not laminated foam—AFTC 5330 offers superior internal strength, enhanced wet-out, and excellent conformability across flat, curved, textured, or uneven surfaces.

The tape uses a high-tack, polymer-optimized acrylic adhesive system that bonds exceptionally well to engineered plastics including ABS, PVC, acrylic (PMMA), and polycarbonate, as well as coated and painted surfaces.

AFTC 5330 Direct Foam Tape is widely used in automotive interiors, electronics housings, HVAC plastics, signage, displays, appliances, and OEM production lines, where reliable long-term adhesion is essential.

Applications

Plastic-to-plastic bonding in consumer electronics and device housings

Automotive interior trim, bezels, and decorative plastic assemblies

HVAC and appliance polymer component mounting

Acrylic panels, signage, graphic displays, and POP assemblies

Composite-to-plastic joining in lightweight structures

OEM manufacturing needing high-performance bonding on polymers

Key Properties

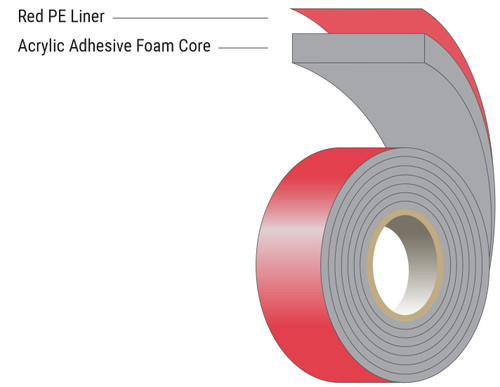

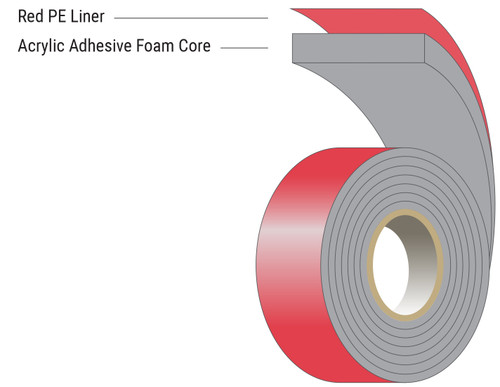

Material Type: Direct-foamed acrylic foam adhesive tape

Adhesive System: High-tack acrylic adhesive engineered for plastics

Core Structure: Integrated acrylic direct-foam core (no lamination)

Adhesion Strength: Strong adhesion to ABS, PMMA, PC, PVC, and coated plastics

Peel Strength: High peel strength suitable for permanent installations

Shear Strength: Suitable for structural and semi-structural bonding loads

Conformability: Excellent on textured, curved, and uneven plastic surfaces

Durability: Resistant to UV, chemicals, solvents, and outdoor exposure

Thermal Stability: Maintains bond strength across temperature cycling

Convertibility: Ideal for die-cutting and automated OEM assembly

FAQs

What is AFTC 5330 Direct Foam Tape used for?

AFTC 5330 is used for bonding plastics, composites, and coated materials in automotive interiors, electronics housings, appliances, HVAC systems, signage, and OEM manufacturing.

How is AFTC 5330 Direct Foam different from standard acrylic foam tapes?

AFTC 5330 is direct-foamed, meaning:

Higher cohesive strength

Better stress absorption

Superior vibration damping

Enhanced bonding to textured or uneven surfaces

No failure-prone lamination layer

Which plastics does AFTC 5330 bond most effectively?

It bonds exceptionally well to:

ABS

Acrylic (PMMA)

Polycarbonate (PC)

PVC

Painted plastics

Powder-coated or coated surfaces

Composite substrates

Is AFTC 5330 suitable for outdoor applications?

Yes. The tape provides long-term resistance to:

UV radiation

Moisture and humidity

Temperature cycling

Environmental chemicals

Vibration and impact

Can AFTC 5330 be supplied as custom die-cut parts?

Yes. H-O Products offers precision die-cut AFTC 5330 components for automated OEM assembly, ensuring clean, consistent, and repeatable bonding performance.

Contact H-O Products today to order AFTC 5330 Direct Foam Tape in rolls, logs, or custom die-cut formats — or request engineer-level support to optimize your polymer or composite bonding project - contact us.