Product Overview

AFTC 5336 General Purpose Tape — Technical Overview & FAQs

Product Overview

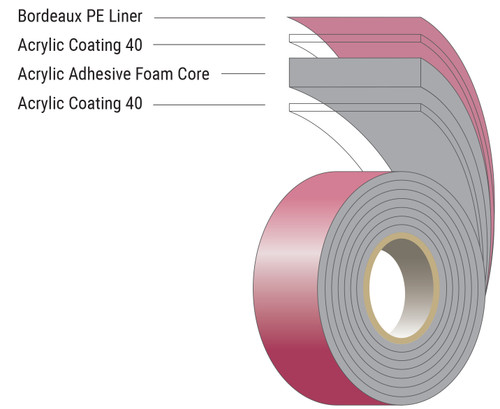

AFTC 5336 General Purpose Tape is a high-strength acrylic foam bonding tape designed for permanent adhesion across a wide range of industrial, automotive, construction, and manufacturing applications.

Its next-generation viscoelastic acrylic foam core provides exceptional conformability, impact absorption, and stress dissipation—allowing it to replace rivets, screws, clips, welds, and liquid adhesives in structural and semi-structural assemblies.

Engineered for harsh outdoor environments, AFTC 5336 offers excellent UV resistance, temperature stability, moisture resistance, and long-term durability, making it ideal for applications where reliability and high bond performance are essential.

AFTC 5336 bonds strongly to metals, plastics, composites, glass, and painted surfaces and is widely used in appliances, automotive trim, HVAC systems, signage, and architectural components.

Applications

Structural and semi-structural bonding

Automotive exterior trim, panels, moldings, and emblems

HVAC panels, access doors, and equipment housings

Appliance and electronics assembly

Signage, nameplates, and architectural mounting

Plastic-to-metal bonding and composite assemblies

Replacement for fasteners, rivets, and adhesives

Key Properties

Material Type: High-bond acrylic foam tape

Adhesive System: Advanced acrylic adhesive with high tack and strong cohesion

Core: Viscoelastic foam absorbs vibration, impact, and mechanical stress

Adhesion Strength: Excellent adhesion to metals, plastics, composites, and coatings

Shear Strength: High — suitable for static and dynamic loading

Peel Strength: Strong permanent peel adhesion

Temperature Range: Maintains bond across wide thermal conditions

Environmental Durability: UV-resistant, water-resistant, solvent-resistant, weather-stable

Outdoor Capability: Ideal for exterior automotive and architectural applications

Convertibility: Easily die-cut for custom OEM shapes and automated production use

FAQs

What is AFTC 5336 General Purpose Tape used for?

AFTC 5336 is used for structural bonding and permanent attachment in automotive, industrial, HVAC, appliance, and signage applications—where high-strength performance is required.

What differentiates AFTC 5336 from AFTC 5335 or 5333?

AFTC 5336 provides:

Higher cohesive strength

Enhanced adhesive durability

Superior performance in high-vibration environments

Stronger adhesion to coated surfaces and metals

Improved environmental resistance

Does AFTC 5336 work well outdoors?

Yes — it is engineered for long-term outdoor use with excellent resistance to:

UV light

Temperature cycling

Moisture and humidity

Environmental exposure

Can AFTC 5336 bond to plastics and composites?

Yes — it bonds strongly to medium- and high-surface-energy plastics, composite panels, and painted components.

Priming is recommended for low-surface-energy materials.

Can AFTC 5336 be die-cut into custom parts?

Absolutely. H-O Products manufactures precision die-cut AFTC 5336 adhesive components for OEM production, automated assembly, and specialized bonding applications.

Contact H-O Products today for AFTC 5336 General Purpose Tape in rolls, master logs, custom die-cut parts, or engineering support for your bonding requirements - contact us.