Product Overview

AFTC 5341 is a double sided general purpose acrylic based adhesive tape, which is especially designed for the bonding of high and medium energy substrates like PVC and ABS. It is capable of absorbing the differing thermal expansions of two different materials. This acrylic foam tape has a very high initial tack. AFTC 5341 is an alternative to 3M 4941, RP45 and CV45F. Click here to view our AFTC & 3M Tapes Technical Comparison.

AFTC 5341 General Purpose Tape — Technical Overview & FAQs

Product Overview

AFTC 5341 General Purpose Tape is a high-performance, double-sided acrylic foam bonding tape engineered for applications requiring exceptionally strong adhesion, outstanding durability, and long-term environmental stability. With its advanced viscoelastic acrylic foam core, AFTC 5341 absorbs mechanical stress, vibration, and thermal expansion—making it a powerful alternative to mechanical fasteners such as rivets, screws, welds, spot welds, and liquid adhesives.

This tape provides excellent bonding to metals, composites, glass, and medium/high–surface-energy plastics, making it widely used across automotive, industrial manufacturing, HVAC, appliance assembly, electronics, and architectural applications.

AFTC 5341 offers enhanced cohesive strength, improved peel resistance, and long-term outdoor weatherability, making it ideal for demanding structural and semi-structural bonding.

Applications

Industrial bonding and component assembly

Automotive exterior trim, emblems, moldings, and panels

Signage, displays, and architectural panel attachment

HVAC and appliance bonding

Composite-to-metal and plastic-to-metal attachment

Electronics mounting and device assembly

Replacement for screws, welds, rivets, or conventional adhesives

Key Properties

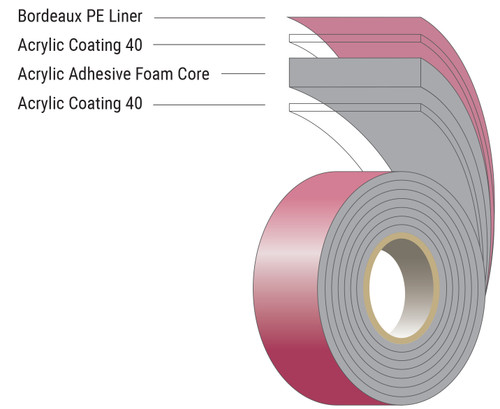

Material Type: High-bond double-sided acrylic foam tape

Adhesive Type: Reinforced high-performance acrylic adhesive

Core: Viscoelastic acrylic foam for stress distribution and shock absorption

Bond Strength: Excellent adhesion to metals, composites, glass, and painted surfaces

Shear Strength: High — suitable for static and dynamic loads

Peel Strength: Exceptional long-term peel adhesion

Temperature Resistance: Maintains stable bonding across wide temperature ranges

Environmental Durability: UV-, water-, chemical-, and weather-resistant

Outdoor Stability: Excellent for long-term exterior use

Convertibility: Ideal for precision die-cutting for OEM production

FAQs

What is AFTC 5341 General Purpose Tape used for?

AFTC 5341 is used for structural bonding, particularly in automotive, industrial, HVAC, appliance, and signage applications requiring high-strength adhesion and long-term reliability.

What makes AFTC 5341 different from AFTC 5339 or 5336?

AFTC 5341 delivers:

Higher cohesive strength for structural-grade bonding

Enhanced peel adhesion

Greater performance under heavy vibration

Improved outdoor durability and UV stability

Better bonding to coated metals and glass

Is AFTC 5341 suitable for outdoor applications?

Yes — AFTC 5341 is designed for long-term outdoor exposure and resists:

UV degradation

Moisture and humidity

Temperature cycling

Weather and environmental stress

Does AFTC 5341 bond well to metals, composites, and plastics?

Absolutely. It offers exceptionally strong adhesion to aluminum, steel, painted surfaces, composite panels, acrylics, and high-surface-energy plastics.

Primers may improve performance on low-surface-energy substrates.

Can AFTC 5341 be converted into die-cut parts for OEM use?

Yes — H-O Products produces custom die-cut AFTC 5341 components for automated assembly, electronics manufacturing, automotive production, and industrial bonding.

Contact H-O Products for AFTC 5341 General Purpose Tape in rolls, logs, custom die-cut parts, or engineering support for your bonding and assembly applications - contact us.