Product Overview

AFTC 5351 Low Pressure Tape — Technical Overview & FAQs

Product Overview

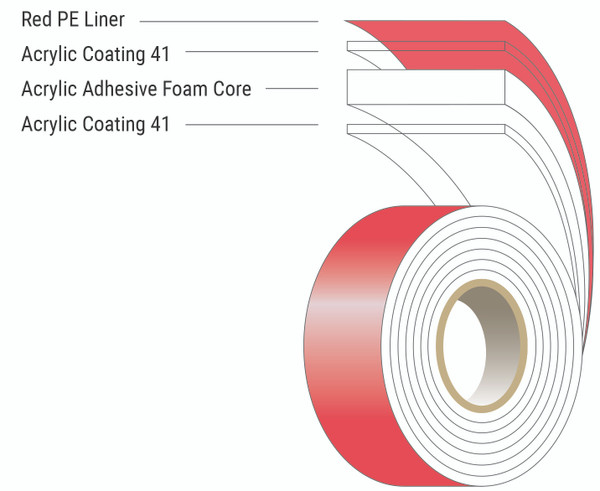

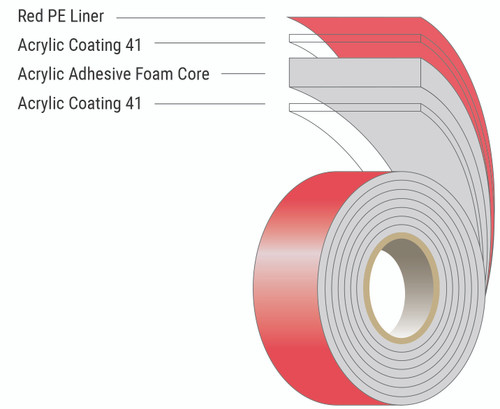

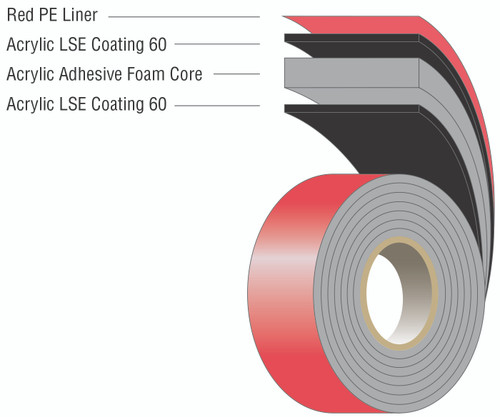

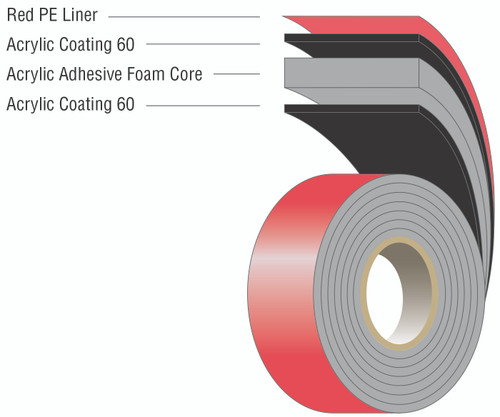

AFTC 5351 Low Pressure Tape is a high-performance low-force acrylic foam bonding tape engineered for applications that require strong adhesion with minimal application pressure. This makes it ideal for assembling lightweight plastics, delicate substrates, thin-gauge materials, and components that cannot withstand high compression during installation.

Built with a soft, conformable viscoelastic acrylic foam core, AFTC 5351 Low Pressure Tape provides excellent wet-out on curved, textured, or uneven surfaces while maintaining superior vibration damping and long-term durability.

The tape bonds exceptionally well to plastics, composites, painted surfaces, and metals, making it a preferred choice for OEM plastic assemblies, electronics housings, automotive interiors, signage, and appliance construction. It replaces mechanical fasteners, clips, rivets, welds, and messy liquid adhesives, offering a clean aesthetic and fast installation.

Applications

Lightweight plastic-to-plastic and plastic-to-metal bonding

Electronics bezels, housings, and device frames

Automotive interior trim, dashboard components, and decorative parts

Flexible plastics and composite bonding

Signage, POP displays, and graphics installation

Appliance assembly and consumer product manufacturing

Low-force assembly lines and delicate substrate applications

Key Properties

Material Type: Low-pressure, ultra-conformable acrylic foam tape

Adhesive System: Soft, high-tack acrylic adhesive optimized for low-force bonding

Foam Core: Conformable viscoelastic foam ideal for textured and curved surfaces

Bonding Pressure Requirement: Very low — adhesion activates with minimal force

Adhesion Strength: Strong adhesion to plastics, composites, and coated surfaces

Shear Strength: High for light and medium-duty structural bonding

Peel Strength: Excellent long-term peel durability

Flexibility: Designed for substrates that flex, curve, or thermally expand

Thermal Performance: Withstands broad temperature fluctuations

Environmental Resistance: UV-, moisture-, and solvent-resistant

Convertibility: Perfect for precision die-cutting for OEM manufacturing

FAQs

What is AFTC 5351 Low Pressure Tape used for?

AFTC 5351 is used for low-force bonding applications, including electronics housings, automotive interior trim, signage, lightweight composite panels, and consumer product assembly.

How is AFTC 5351 Low Pressure Tape different from standard AFTC 5351?

The Low Pressure variant:

Requires significantly less application force

Offers improved conformability for uneven surfaces

Is optimized for flexible or delicate substrates

Provides better adhesion on lightweight plastics

Does AFTC 5351 Low Pressure Tape bond well to plastics?

Yes — it is specifically engineered for plastics including:

ABS

PVC

Acrylic

Polycarbonate

Painted and coated polymers

Its low-pressure adhesive improves wet-out on substrates difficult for standard tapes.

Is AFTC 5351 Low Pressure Tape suitable for outdoor environments?

Yes. It resists:

UV exposure

Moisture and humidity

Temperature cycling

Environmental weathering

(Ensure compatibility with the specific plastic substrate for long-term outdoor use.)

Can AFTC 5351 Low Pressure Tape be supplied as custom die-cut components?

Yes. H-O Products manufactures precision die-cut Low Pressure 5351 parts for OEM production lines and automated assembly.

Contact H-O Products today to order AFTC 5351 Low Pressure Tape in rolls, logs, or custom die-cut formats — or request engineering support to optimize your plastic or composite bonding application - contact us.