Product Overview

AFTC 5353 Low Pressure Tape — Technical Overview & FAQs

Product Overview

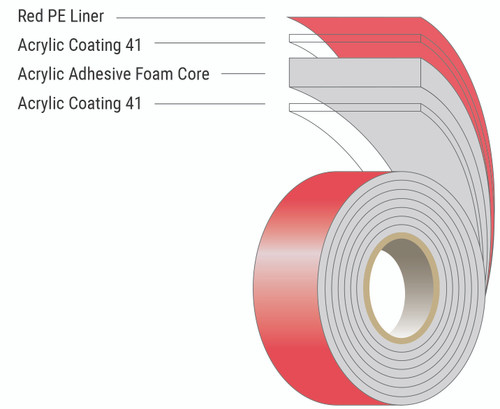

AFTC 5353 Low Pressure Tape is a soft, highly conformable acrylic foam bonding tape engineered for assemblies that require strong adhesion with minimal application pressure.

This low-pressure adhesive system is ideal for bonding lightweight plastics, delicate substrates, flexible components, and parts that cannot tolerate high compression during installation.

The viscoelastic acrylic foam core provides excellent gap-filling capability, vibration damping, and consistent stress distribution across plastic, composite, and coated surfaces.

AFTC 5353 Low Pressure Tape offers a clean, permanent alternative to mechanical fasteners, clips, rivets, welds, and liquid adhesives, making it ideal for OEM production and automated assembly environments.

It is widely used in electronics, automotive interiors, appliances, signage, and lightweight composite assemblies where low-force installation is essential.

Applications

Plastic-to-plastic and plastic-to-metal bonding under low pressure

Electronics housings, bezels, and device frames

Automotive interior trim, dashboard components, decorative accents

Lightweight composites and flexible polymer assemblies

Signage, graphic panels, and POP displays

Appliance construction and consumer product assembly

Low-force industrial assembly environments

Key Properties

Material Type: Low-pressure acrylic foam bonding tape

Adhesive System: Soft, aggressive-tack acrylic adhesive for minimal-force bonding

Foam Core: Conformable viscoelastic acrylic foam compensates for irregular surfaces

Bond Activation Pressure: Very low pressure needed to achieve full adhesion

Adhesion Strength: Excellent bonding to plastics, composites, and coated surfaces

Shear Strength: High for lightweight and medium-duty structural applications

Peel Strength: Strong long-term peel resistance for permanent installations

Flexibility: Ideal for curved, textured, or delicate substrates

Environmental Resistance: UV-, moisture-, weather-, and solvent-resistant

Thermal Performance: Reliable adhesion across extreme temperature cycling

Convertibility: Easily converted into precision die-cut components

FAQs

What is AFTC 5353 Low Pressure Tape used for?

AFTC 5353 Low Pressure Tape is used for low-force bonding applications, particularly with plastics, composites, thin-gauge materials, and flexible assemblies used in electronics, automotive interiors, and appliances.

How does AFTC 5353 Low Pressure differ from standard AFTC 5353?

The Low Pressure version:

Activates adhesion with minimal force

Has a softer adhesive system

Is highly conformable for challenging surface geometries

Performs better on delicate or flexible substrates

What plastics does AFTC 5353 Low Pressure Tape bond well to?

It is engineered to bond to:

ABS

PVC

Acrylic

Polycarbonate

Painted plastics

Coated plastics

Its soft adhesive improves wet-out on substrates difficult for standard foam tapes.

Is AFTC 5353 Low Pressure Tape suitable for outdoor applications?

Yes — it is designed to resist:

UV exposure

Moisture & humidity

Temperature extremes

Environmental weathering

However, compatibility should be confirmed for certain soft or highly flexible plastics used outdoors.

Can AFTC 5353 Low Pressure Tape be supplied as die-cut components?

Yes. H-O Products provides custom die-cut AFTC 5353 Low Pressure adhesive parts for OEM and automated manufacturing applications.

Contact H-O Products today to order AFTC 5353 Low Pressure Tape in rolls, logs, or precision die-cut formats — or request engineering assistance for your plastic or composite assembly - contact us.