Product Overview

AFTC 5359 Direct Foam Tape — Technical Overview & FAQs

Product Overview

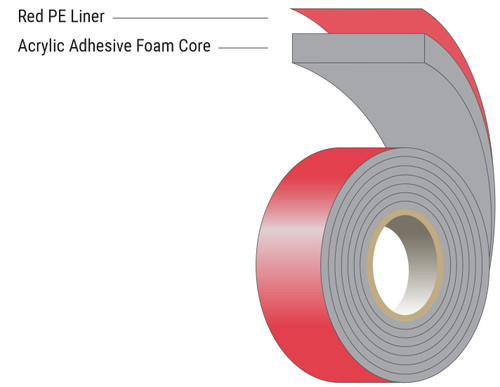

AFTC 5359 Direct Foam Tape is a premium-strength, high-performance acrylic direct-foam bonding tape designed for demanding structural and semi-structural polymer bonding applications.

Its monolithic direct-foam acrylic core (not laminated) delivers exceptional cohesive strength, enhanced stress distribution, and superior long-term durability compared to traditional acrylic foam tapes.

AFTC 5359 incorporates a high-tack, high-strength acrylic adhesive optimized for engineered plastics such as ABS, acrylic (PMMA), polycarbonate (PC), PVC, and coated polymer surfaces. It delivers outstanding wet-out, even on textured, uneven, low-energy, or complex geometries.

This tape is engineered for high-load, high-vibration, and harsh-environment applications, making it ideal for automotive interiors, appliance manufacturing, electronics housings, composite bonding, outdoor signage, HVAC plastics, and OEM assembly lines.

Applications

High-strength structural plastic bonding

Electronics housings, enclosures, frames, and plastic shells

Automotive interior components, trim, bezels, and decorative plastics

Permanent mounting of signage, panels, and acrylic displays

Plastic-to-metal and composite-to-plastic bonding

HVAC and appliance polymer assemblies

OEM manufacturing where long-term reliability is required

Key Properties

Material Type: High-strength acrylic direct-foam bonding tape

Adhesive System: High-tack, high-strength acrylic adhesive optimized for plastics

Foam Structure: Monolithic direct-foam acrylic core for superior internal strength

Adhesion Strength: Exceptional adhesion to ABS, PVC, acrylic, PC, and coated plastics

Peel Strength: Very high peel strength for permanent applications

Shear Strength: High structural shear performance for demanding loads

Conformability: Excellent surface wet-out on curved, textured, and uneven plastics

Environmental Resistance: UV-, moisture-, chemical-, and weather-resistant

Thermal Stability: Performs reliably under heat, cold, and rapid cycling

Convertibility: Suitable for precision die-cut OEM production

FAQs

What is AFTC 5359 Direct Foam Tape used for?

AFTC 5359 is used for high-strength bonding of plastics, metals, and composites in applications requiring long-term durability, including automotive components, electronics housings, HVAC units, signage, and OEM-grade assemblies.

How does AFTC 5359 differ from other AFTC direct-foam tapes like 5350 or 5313?

AFTC 5359 offers:

Higher structural shear strength

Superior peel adhesion on coated or painted plastics

Improved dynamic performance under vibration and impact

Greater environmental durability

Stronger bonding to difficult plastics

It is a flagship-grade direct-foam tape in the AFTC line.

Which plastics does AFTC 5359 bond most effectively?

AFTC 5359 bonds extremely well to:

ABS

PVC

Acrylic (PMMA)

Polycarbonate (PC)

Painted plastics

Powder-coated surfaces

Composites and coated polymers

Is AFTC 5359 suitable for harsh outdoor applications?

Yes. It is engineered to withstand:

Intense UV exposure

Moisture, humidity, and weathering

Solvents and environmental chemicals

Thermal cycling and rapid temperature changes

Mechanical vibration and dynamic loads

Can AFTC 5359 be supplied as custom die-cut parts?

Yes. H-O Products manufactures precision die-cut AFTC 5359 components for automated OEM production, ensuring consistent bonding and streamlined assembly.

Contact H-O Products today to order AFTC 5359 Direct Foam Tape in rolls, logs, or precision die-cut configurations — or request engineer-level support to determine the ideal bonding solution for your application - contact us.