Why Aerospace Gaskets Are Different

In aerospace engineering, every ounce of material, every temperature threshold, and every safety rating carries significant weight. Unlike standard industrial gaskets, aerospace gaskets must meet incredibly strict performance and compliance criteria - ensuring reliability in environments where failure is not an option.

At H-O Products, we specialize in converting advanced gasketing materials that are engineered specifically for aerospace applications - from cabin seals and ducting insulation to EMI shielding and flame barriers.

Performance Requirements: What Separates Aerospace from Industrial

When selecting gasket materials for aerospace systems, engineers typically prioritize the following:

- Weight-to-performance ratio

Every component is weight-sensitive. Low-density closed-cell foams or thin-gauge solid silicones are often used to minimize load without compromising seal integrity. - Extreme temperature performance

Materials must remain resilient in conditions ranging from sub-zero altitudes to engine-adjacent heat zones. This calls for high-temp silicone rubber, foams, and fluorosilicone blends withstanding 400–500°F and beyond. - Flame resistance / flammability compliance

Cabin components and internal systems require compliance with UL 94 V-0 or FAR 25.853 flammability standards, often using coated or filled silicone foams. - EMI/RFI shielding

Avionics, flight controls, and navigation systems are vulnerable to electromagnetic interference. EMI shielding gaskets — such as nickel-graphite-filled elastomers — ensure reliable performance in high-frequency environments. - Outgassing / low volatility

NASA, ESA, and other aerospace agencies often specify low total mass loss (TML) and collected volatile condensable materials (CVCM) for materials used in sealed or sensitive areas.

Compliance Standards: What You Need to Know

To be considered aerospace-grade, gasket materials often need to meet or exceed the following:

- UL 94 V-0: Vertical burn test for flame retardancy (self-extinguishing within 10 seconds)

- FAR 25.853: Flammability of materials used in aircraft cabin interiors

- ASTM D1056: Foam cell structure, compression resistance, and fluid aging

- MIL-DTL-83528: Shielding gaskets for military/aerospace applications (EMI)

- Outgassing per ASTM E595: Especially for space-bound or hermetically sealed systems

At H-O, we stock and convert multiple materials that meet these standards, including closed-cell silicone foams, specialty EMI elastomers, and low-outgassing sponge.

Common Aerospace Gasket Applications

Some of the most common areas where aerospace-grade gaskets are used:

|

Application |

Material Considerations |

| Avionics panels | EMI shielding silicone (UL 94 V-0) |

| Access panels | Closed-cell silicone sponge (weatherproof) |

| Interior trim | Low-density UL 94-rated foam |

| Engine seals | High-temp solid silicone (600°F+) |

| Insulation wraps | Ceramic fiber or aerogel tape |

| Ducting & HVAC | Flame-rated, flexible foam (FAR 25.853) |

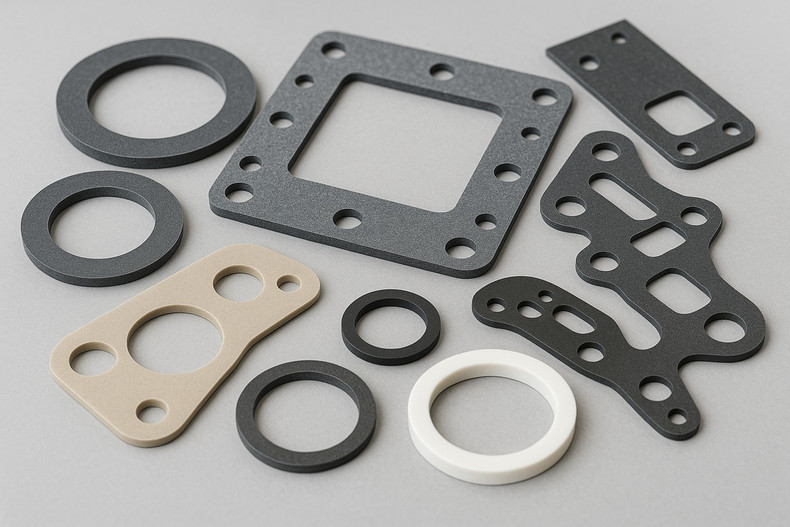

Common Materials Which Can Be Used for Aerospace Gasketing

H-O Products can supply and convert aerospace-ready materials including, but not limited to:

- HT-800 Series Silicone Foam (UL 94 V-0, closed-cell, great resilience)

- RS-800 Series Silicone Sponge (UL 94 V-0, closed-cell, economical grade)

- BF-1000 Soft Silicone Foam (lightweight + compressible)

- Nickel-Graphite Filled Silicone (EMI protection)

- EC-2130 Silicone Foam (ultra-stable EMI-grade base)

- Aerogel insulation wrap (Armagel XGH)

- Peroxide-cured solid silicone (high heat + low compression set)

Why Work with H-O for Aerospace Gaskets?

- ISO 9001-2015 - certified quality system

- Over 50 years of high-spec conversion experience

- Rapid Prototype to production flexibility

- Custom die-cutting, laminating, and slitting in-house

- Experience providing mil-std components

Ready to Improve Your Aerospace Seal?

Whether you’re sealing an avionics panel, insulating an engine compartment, or building a space-rated enclosure, we can help you select the right material and convert it to your exact spec.

About H-O Products

Our engineered products – including foam, rubber, polymeric and composite tapes, pads and gaskets – offering reliable sealing, cushioning, mounting and assembly in harsh environments, while minimizing downtime and maintenance costs. From prototype through final product, our customers can be confident in performance, reliability, and the continued support of our expert team. Learn more about H-O Products and how we can give your company a competitive edge in today’s global marketplace.