Silicone Tapes for High-Temperature and Extreme Environment Applications

Engineered for Performance, Flexibility, and Heat Resistance

Engineered for Performance, Flexibility, and Heat Resistance

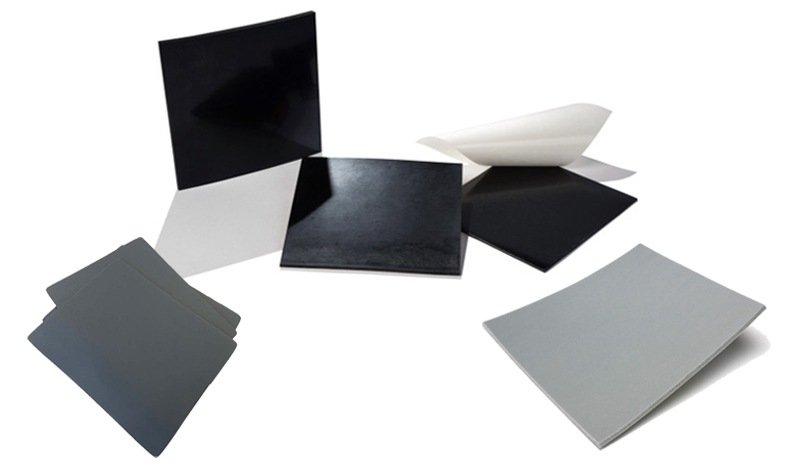

H-O Products’ Silicone Tape line is designed for applications demanding superior heat resistance, electrical insulation, and chemical stability. These tapes provide long-lasting sealing, insulation, and protection for industrial, commercial, and specialty uses, ensuring reliability even under extreme conditions.

Key Features & Benefits

- High Temperature Resistance: Maintains performance in temperatures ranging from -60°F to 500°F depending on product.

- Electrical Insulation: Excellent dielectric strength for insulation of wires, cables, and electrical components.

- Chemical and UV Resistant: Resists moisture, solvents, oils, and UV exposure for extended service life.

- Flexible and Conformable: Easily wraps around irregular surfaces and complex geometries without cracking.

- Self-Fusing or Adhesive-Backed Options: Offers immediate, secure sealing without the need for additional adhesives or mechanical fasteners.

Applications

H-O Products’ Silicone Tapes are trusted across applications that require high heat resistance, chemical stability, and electrical insulation, including:

- Electrical and Electronic Components: Insulation of wires, terminals, and connectors.

- High-Temperature Sealing: Sealing pipes, hoses, and equipment in extreme heat environments.

- Protective Wrapping: Chemical, moisture, and UV-resistant protective wraps for machinery, conduits, and structural components.

- Industrial Assembly and Maintenance: For aerospace, automotive, and specialty manufacturing applications.

Key Markets

H-O Products delivers engineered silicone tape solutions for B2B industries requiring precision, reliability, and durability:

- Automotive: Filtration, cushioning, and separation solutions in vehicles and components.

- Aerospace: Airflow management, vibration damping, and protective applications in aircraft systems.

- Electronics: Filtration, moisture control, and cushioning for electronic devices and components.

- Heating and Ventilation (HVAC): Air and liquid filtration, sound insulation, and cushioning in HVAC systems.

- Lighting: Shock absorption, vibration damping, and thermal management in lighting systems.

- Marine: Filtration, protection, and cushioning for marine equipment and components.

- Military: High-performance filtration, sealing, and protection for military-grade systems and equipment.

- Rail: Vibration damping, noise reduction, and protection for rail components and systems.

Why Choose H-O Products’ Silicone Tapes?

H-O Products’ Silicone Tapes are engineered to provide consistent performance in the harshest environments. With superior heat resistance, flexibility, and chemical stability, our tapes ensure that your electrical, industrial, and assembly applications remain safe and reliable. Custom engineering options allow for application-specific solutions, improving installation efficiency and long-term reliability.

For more information on our premium Silicone Tapes and to explore our product offerings, visit our Silicone Tapes page.

Contact Us today to discuss how H-O Products’ Silicone Tapes can meet your high-performance, extreme environment, and specialty application needs.