Product Overview

RS-800 Medium Silicone Sponge — Technical Overview & FAQs

Product Overview

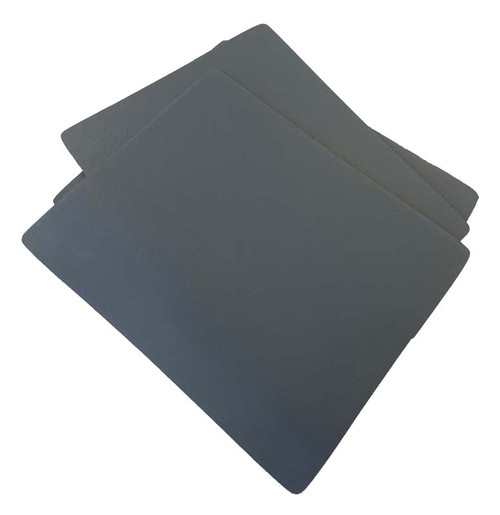

RS-800 is a medium-density, closed-cell silicone sponge designed to combine the lightweight characteristics of foam with the sealing performance of sponge rubber. It is engineered for durable gasketing, gap-filling, vibration isolation and environmental sealing in a wide range of industries. Its closed-cell structure provides excellent resistance to water, dust and air ingress, while offering flame resistance and long-term stability from low to high temperatures.

Key Properties

Typical density is approximately 25 lb/ft³. Compression force deflection is about 11.5 psi (ASTM D1056) for common thicknesses. Compression set after 22 hours at 212 °F and 50% compression is about 4%. Water absorption is around 1%. Operating temperature ranges from about -67 °F to +392 °F. The material meets UL 94 V-0 and UL 94 HF-1 flame classifications and resists UV, ozone and environmental aging.

FAQs

What is RS-800 silicone sponge?

RS-800 is a medium closed-cell silicone sponge material offering a balance of compressibility and durability, combining foam-like weight with sponge-rubber sealing strength.

Where is RS-800 typically used?

It is commonly used for environmental seals in outdoor enclosures, lighting fixtures, HVAC units, electronic cabinets, as well as vibration isolation and gap-filling in transportation and industrial equipment.

What performance advantages does RS-800 offer?

It offers a closed-cell structure that limits water absorption, retains elasticity over time (low compression set), operates over a wide temperature range, and has flame-resistant properties.

Can RS-800 be die-cut or supplied with adhesive?

Yes. RS-800 is available in sheet and roll formats, and can be custom die-cut into gaskets, tapes or pads. Adhesive-backed versions may also be available.

Contact H-O Products to request RS-800 samples, technical datasheets, or custom gasket fabrication - contact us.

Read more about why Aerospace Gaskets are Different here.