Product Overview

55 Durometer FDA Grade Industrial Polychloroprene (Solid Neoprene) — Technical Overview & FAQs

Product Overview

This 55 durometer FDA grade industrial polychloroprene (neoprene) is a medium-firm, solid elastomer engineered for applications requiring non-toxic, food-safe sealing, mechanical strength, and environmental resistance.

Formulated with FDA-approved ingredients (per 21 CFR 177.2600), it’s ideal for gaskets, seals, and pads in food processing, pharmaceutical, and general-industrial environments where cleanliness and durability are essential.

Its balanced 55 Shore A hardness provides firm yet flexible performance for die-cut gaskets, isolation mounts, and vibration-control pads. The material also resists ozone, sunlight, mild oils, and cleaning agents, maintaining elasticity and compression recovery over extended service life.

Applications

FDA-compliant seals and gaskets for food and beverage processing equipment

Sanitary pads, isolation washers, and enclosure seals

Pharmaceutical and laboratory equipment gasketing

Industrial machinery requiring clean, oil-resistant seals

Custom die-cut or adhesive-backed parts for hygienic environments

Key Properties

Hardness: Shore A 55 ± 5 (ASTM D2240)

Tensile Strength: ≥ 800 psi (ASTM D412)

Elongation at Break: ≥ 250 % (ASTM D412)

Compression Set (22 h @ 158 °F): ≤ 25 %

Temperature Range: –20 °F to +220 °F (–29 °C to 104 °C)

Polymer Type: Polychloroprene (CR)

Specific Gravity: ~ 1.38 g/cc

Finish: Smooth finish, powder-free surface

Color: Off-white (FDA-compliant pigment)

Compliance: FDA 21 CFR 177.2600 & RoHS compliant

Environmental Resistance: Excellent ozone and weather resistance; moderate oil resistance

FAQs

What is 55 durometer FDA grade industrial polychloroprene used for?

It’s used for food-grade gaskets, pads, and seals where FDA compliance, durability, and moderate oil resistance are required — ideal for food equipment and industrial applications.

What makes this neoprene different from commercial grades?

This formulation uses FDA-approved ingredients and maintains non-toxic performance, making it suitable for contact with food, water, and clean-room environments.

Can this material handle temperature extremes?

Yes — it operates reliably from –20 °F to +220 °F (–29 °C to 104 °C), retaining sealing integrity under moderate thermal cycling.

Is it resistant to cleaning chemicals and oils?

Yes — it resists mild oils, detergents, and sanitizing agents used in industrial and food-processing maintenance cycles.

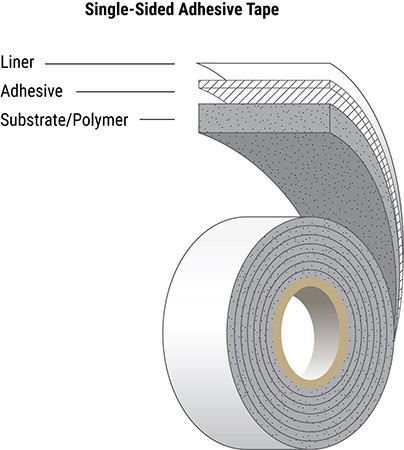

Can it be custom fabricated or adhesive-backed?

Yes — it’s available as sheets, rolls, or die-cut gaskets, and can be laminated with FDA-compliant adhesives for peel-and-stick installation.

Contact H-O Products for FDA Grade 55 Durometer Polychloroprene Neoprene samples, technical data sheets, or custom die-cut solutions for your industrial and sanitary sealing applications - contact us.